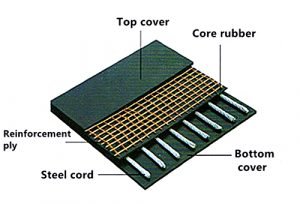

Bucket elevator conveyor belt is a kind of steel cord conveyor belt. It has the advantages of high tensile strength, good impact resistance, long using life, small elongation, good groove formation features, can be suitable for long distance, large transportation range and high speed for conveying materials. The belt is made up of rubber cover,steel cord,core rubber,reinforcement layer.

Application

The belt is suitable for coal mine, mine, port, electric power, metallurgy, building materials and other industries, and can be used for long distance, large span, large volume and high speed material transportation.

Feature

The bucket elevator conveyor belt has the advantages of mildew prevention, moth-proof, anti-aging, good heat resistance, high tear resistance strength and can be renovated after surface failure. Features a large tensile strength. Good impact resistance, long life, small elongation, good groove formation, good bending resistance, suitable for long interval, large range, high speed to transport materials.

Advantage

1, High tensile strength, high safety factor;

2, Small elongation, short tension travel distance;

3, Steel cord and rubber combined firmly, excellent dynamic performance;

4, Soft rubber cover , good groove, good straight line operation;

6, Reliable joint, long service life.

Technical performance

(1) All performance meet GB9770;

(2) Cover glue performance users if they have special requirements, please contact us;

(3) Impact resistance and tear resistance can improve the impact resistance by 1~2 times, and improve the tear resistance by 0.5~1 times;

(4) The lowest working temperature of cold resistance type is-60℃.

(5) Can produce the belt according to customer request standard.

Production Standard

General type standard GB/T9770-2001,cold resistant Q/FXS05-2002,flame-resistant G2539-93,acid-resistant Q/FXS02-2002,heat resistant Q/FXS08-2001, tear-resistant HG/T3646-1999, flame-resistant MT668-1997.

| Type | Standard |

| General Type steel cord belt | GB/T9770-2001 |

| Flame-retardant type steel cord conveyor belt | MT668-1997 |

| General flame-retardant type Steel cord conveyor belt | MT668-1997 |

| Heat-resistant Steel cord conveyor belt | HG2297-92 |

| Wear-resistant Steel cord conveyor belt | Shore Abrasion≤90mm 3 |

| Acid,alkali,oil resistant Steel cord conveyor belt | HG4-846 |

| Cold-resistant Steel cord conveyor belt | Fragile temperature: -40℃ |

Steel cord belt Technical data sheet(Table 1,Table 2,Table3)

Table 1:

| Item | St

630 |

St

800 |

St

1000 |

St

1250 |

St

1600 |

St

2000 |

St

2500 |

St

3150 |

St

3500 |

St

4000 |

St

4500 |

St

5000 |

St

5400 |

| Tensile Strength,N/mm | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 |

| Diameter,mm | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 |

| Pitch,mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Top cover,mm | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 |

| Bottom cover,mm | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8.5 | 9 |

Table 2:

| Belt width ,mm | Number of steel cord | ||||||||||||

| St

630 |

St

800 |

St

1000 |

St

1250 |

St

1600 |

St

2000 |

St

2500 |

St

3150 |

St

3500 |

St

4000 |

St

4500 |

St

5000 |

St

5400 |

|

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | ||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 59 | 55 | 55 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 77 | 77 | 71 | 66 | 66 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 90 | 90 | 84 | 78 | 78 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 104 | 104 | 96 | 90 | 90 |

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 117 | 117 | 109 | 102 | 102 | |

| 2000 | 159 | 159 | 159 | 159 | 128 | 128 | 130 | 130 | 121 | 113 | 113 | ||

| 2200 | 176 | 141 | 141 | 144 | 144 | 134 | 125 | 125 | |||||

| 2400 | 193 | 155 | 155 | 157 | 157 | 146 | 137 | 137 | |||||

| 2600 | 209 | 168 | 168 | 170 | 170 | 159 | 149 | 149 | |||||

| 2800 | 194 | 194 | 171 | 161 | 161 | ||||||||

Table 3:

| Item | Tensile strength,MPa ≥ | Rate at elogation break,% ≥ | Shore,mm 3 ≤ |

| D | 18 | 400 | 90 |

| H | 25 | 450 | 120 |

| L | 20 | 400 | 150 |

| P | 14 | 350 | 200 |